Business

Extending Equipment Life Through Expert ZF Off-Highway Transmission Repair

hanery hasan

hanery hasan

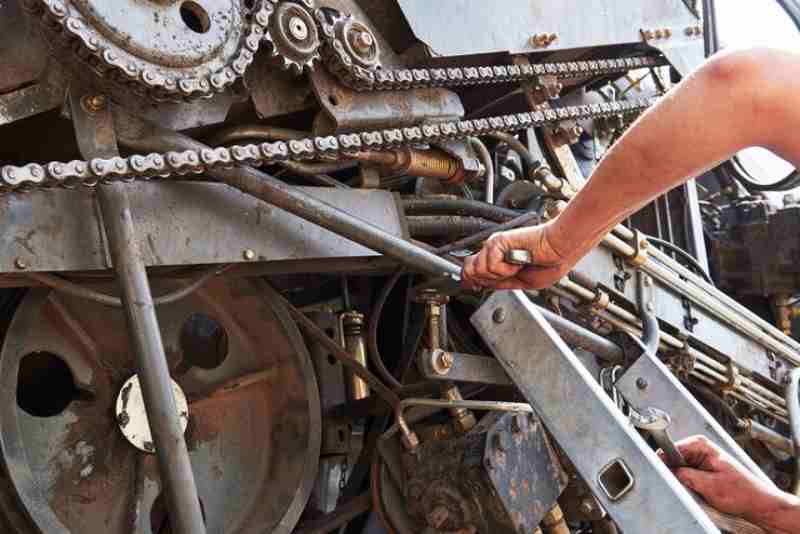

The service life of heavy-duty, off-highway equipment is directly proportional to the quality of transmission repair and maintenance it receives. Specialized components like ZF transmissions demand a higher level of care and diagnostic accuracy than typical automotive parts. Maximizing the operational lifespan of these expensive assets is a key objective for every business relying on industrial machinery.

Proper, expert attention can dramatically delay the need for costly replacements or premature equipment retirement. Focusing on specialized repair techniques and the use of high-quality components ensures that the transmission performs as originally intended. This focus on durability is especially critical in demanding sectors such as construction, rail transport, and material handling operations.

The Specifics of ZF Off-Highway Transmission Repair

ZF transmissions are engineered to handle the extreme loads and harsh conditions inherent in off-highway and heavy-duty applications worldwide. Their intricate design requires technicians to possess specific knowledge of their hydraulic and electronic control systems. Attempting a repair without this crucial specialization often leads to compounded mechanical issues and further expense down the road.

A professional service provider will possess the necessary tools and technical documentation to approach these complex repairs systematically. They specialize in identifying failures unique to the ZF design, ensuring that all replacement or remanufactured parts meet stringent OEM standards. This expertise is the foundation of durable and reliable ZF Off-Highway transmission repair service.

Components Requiring Specialized Attention

Within the complex ecosystem of a ZF transmission, certain components frequently require specialized attention during maintenance and overhaul procedures. These may include sophisticated clutch packs, advanced torque converters, and specialized electronic control modules which govern gear shifting. Each part must be inspected and serviced individually to ensure seamless integration back into the main system.

Technicians also pay close attention to the various sensors and valving, often requiring replacement parts like WABCO ABS sensor replacements or air brake components. Using genuine, high-quality parts for these critical systems is non-negotiable for ensuring safe and effective equipment operation. Inferior parts can compromise both the performance and the critical safety features of the machinery being serviced.

The Role of Remanufactured OEM Units

Remanufactured OEM transmissions are often the most practical and efficient solution for bringing downed heavy equipment back online quickly. These units are built from core transmissions, meticulously disassembled, inspected, and rebuilt with new internal wear parts. They represent a significant commitment to quality, offering reliability comparable to a brand-new unit but with much faster availability.

For companies operating critical equipment, having access to an established inventory of these specialized remanufactured units is a major advantage. It means that the long wait times often associated with procuring brand-new, niche transmissions can be substantially mitigated. This efficient service model supports operational continuity for vehicles across categories, including bus, rail, and marine equipment.

Precision Transmission and Comprehensive Service

When choosing a service partner for heavy-duty transmission needs, their commitment to comprehensive care is perhaps the most telling measure of their value. A true expert provides a full suite of services ranging from initial detailed diagnostics to final performance testing and ongoing technical support. This holistic approach ensures all related systems are in excellent operational condition upon return.

They understand that quality is a long-term investment, recognizing that the best work ultimately saves the client money by preventing costly repeat failures. Services by experts at are focused on providing superior heavy-duty transmission solutions across the entire United States. They stand behind their work because they prioritize professionalism, attention to detail, and customer satisfaction above all else in their industry.

Servicing a Broad Range of Equipment Types

Heavy-duty experts must demonstrate proficiency across numerous equipment categories, not just a select few niche markets. Their comprehensive services must extend to complex machines like cranes and specialty equipment used in diverse and demanding applications. This broad capability means that fleet managers only need a single point of contact for nearly all their transmission-related problems.

The types of machinery covered include all ground support vehicles, crucial for aviation operations, and essential material handling components used in logistics. Even specialized rail and marine transmissions fall within their wheelhouse of expertise and service capacity. This versatility ensures that virtually any heavy piece of equipment, regardless of its industry role, can receive expert-level care efficiently.

Commitment to Customer Support and Communication

Exceptional heavy-duty transmission service is underpinned by outstanding customer service and clear communication throughout the entire repair process. Clients value accessibility to experts who can clearly explain the diagnosis, the necessary repair steps, and the expected timeline. This transparency builds crucial trust between the service provider and the essential businesses they are supporting daily.

Experts offer ways to easily request a callback or engage in direct communication with technical support personnel when questions arise. Whether you need on-site support for installation or simply have complex questions, help should be readily available and responsive. This dedication to communication is just as vital to reducing downtime as the mechanical expertise provided in the service bay.

Conclusion

Extending the life and maximizing the performance of heavy equipment requires specialized attention to its most critical component: the transmission. Services covering intricate systems like ZF Off-Highway transmission repair must be performed by dedicated professionals adhering to the highest quality standards. By partnering with experts who prioritize precise diagnostics, quality remanufactured parts, and rapid service, equipment owners secure their investments. This ensures continuous, reliable operation and safeguards long-term profitability in demanding industrial sectors across the nation.

Source:

Click for the: Full Story

You might like

Close Menu

Close Menu