Business

Slash Energy Bills with Advanced Peptide Purification Systems

Peptide Purification drains power in biotech labs. Pumps run hours on columns. Heat cycles spike meters. Advanced systems cut that load. Membrane methods run cold and flat. Bills drop sharp. Output holds steady.

Power Drains in Standard Purification

Chromatography setups pull 10 kWh per kg peptide. Pressure builds to 100 bar. Elution steps repeat cycles. Cooling keeps columns from melt. India labs pay grid peaks. USA sites hit utility caps. Buffers waste energy in prep. Resin cleans burn steam. Scale up triples power draw. Downtime adds idle costs.

Top Energy Sinks

- Column pumps tax motors. Gradient makers cycle nonstop. Fraction collectors chill samples. Wash steps refill tanks. Total hits $5 per gram run.

Membrane Shift for Peptide Purification

Membrane Reactor feeds reaction direct to Peptide Purification. Select skins grab target chains. Pressure drops low at 5 bar. Flux pulls clean at 1 kg per m2 hour. No heat jumps over 50C. Electric draw stays 2 kWh per kg. Retentate recycles impurities. Pure permeate skips polish.

Membrane Action Steps

- Feed hits skin face. Small pores block junk. Target slides through easy. Vacuum side grabs vapor. One pass yields 90% pure.

Energy Cuts from Design

Advanced Peptide Purification halves power over columns. Monthly bills fall $15,000 mid lab. Payback lands 9 months. No compressor roars fill plant. Footprint drops 80%. Steel use shrinks half. Pumps idle most shifts. Maintenance skips resin swaps.

Savings by Scale

- Lab runs save $200 per batch. Pilot cuts $2,000 day. Plant scale drops $50,000 month. Numbers track field data. Mid ops see these flat.

Ethanol Dehydration Pairing

Ethanol Dehydration cleans feeds for Peptide Purification. Dry alcohol solvents run membranes clean. Water pulls out first. No haze blocks flux. Rates hold 0.5 kg m2 hour. Power stays low vacuum pull.

Solvent Drying Integration

Solvent drying preps streams bone dry. Trace water quits before Peptide Purification. Membranes last 3x runs. Energy skips dryer heat. Organic loads stay pure. No side binds slow flux.

Drying Key Points

- Vacuum condenses drops fast. Reuse cuts buy 70%. Bills drop from no fresh heat.

Organic Solvent Nanofiltration Role

Organic Solvent Nanofiltration sorts heavies in Peptide Purification. Pores at 1 nm grab chains right. Lights pass clean. Reaction ties back via Membrane Reactor. Yields top 92%. Power draw flat at ambient.

Membrane Reactor Full Loop

- Membrane Reactor runs synthesis inline. Products feed Peptide Purification direct. Separation shifts equilibrium. No product loss mid path.

- Energy loops tight. Total use drops 55%.

Reactor Wins Listed

- Yields climb from pull shift. Catalysts hold 2 years. Recycle cuts feed 40%. Scale adds modules snap.

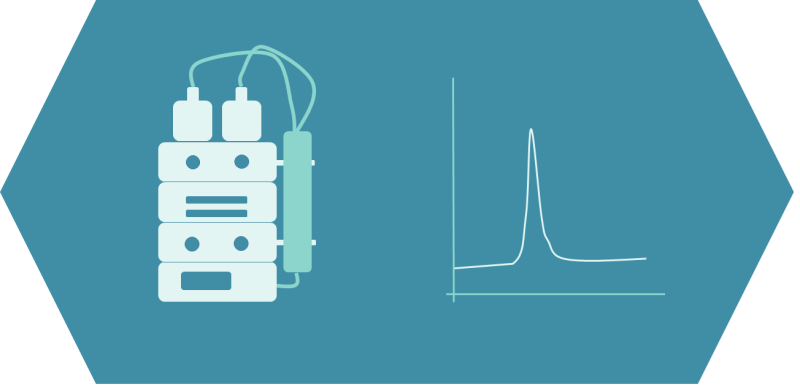

Setup for Low Power Runs

- Pick stream grade first. Test flux on sample. Bolt skid to line. Load membrane pack. Dial pressure slow. Log purity shifts.

- Pilot starts 50 liter day. Full hits 2 tons week.

Lab Gains Over Years

Advanced Peptide Purification rewrites budgets. Margins stack quick. Lines grow low cost. Teams skip grunt work. I3 Nanotec sets up Membrane Reactor, Ethanol Dehydration, Solvent drying, Organic Solvent Nanofiltration, Peptide Purification for power tight ops. Get stream check now.

Source:

Click for the: Full Story

You might like

Close Menu

Close Menu